By Zack Novak, Uptake

The construction industry is on the verge of significant transformation as a result of new digital capabilities. During my time working with customers in the construction industry, I’ve found a shifting sentiment around the use of artificial intelligence (AI). Several years ago, customers were curious – how could AI be implemented in the construction industry or in my business?

More recently, customers are no longer simply curious. The question now is: how fast can I implement AI to derive value from all this data?!

An Overabundance of Data: The Good, The Bad, and The Ugly

As Industrial Internet of Things (IIoT) technologies have gained momentum and made it easier and more cost-effective to connect physical assets to the internet, customers are finding themselves buried in an abundance of machine alerts and data points.

As a result, many are now racing to not only get access to data through increasingly connected machines but also make sense of the data. They want to be able to select the valuable notifications out of the noise of alerts and identify the machine behavior patterns that are truly predictive of potential problems.

How AI Helps with Data Overload

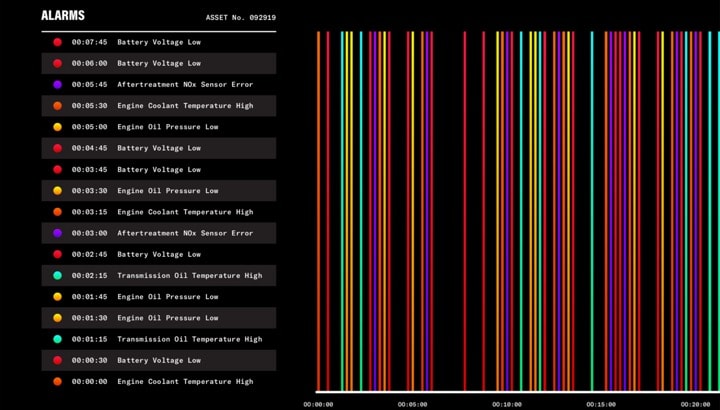

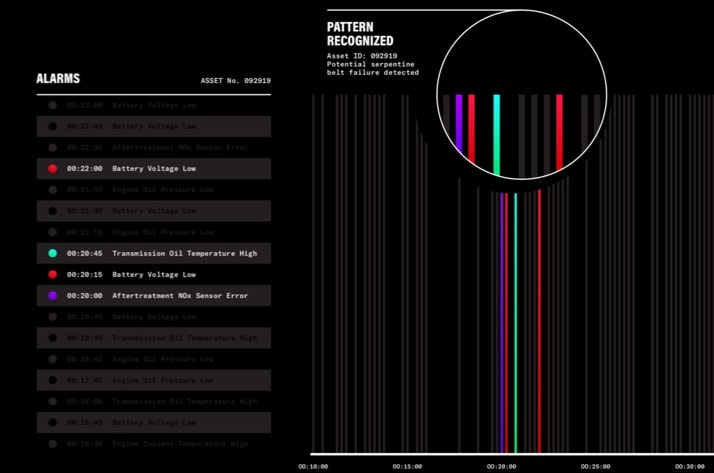

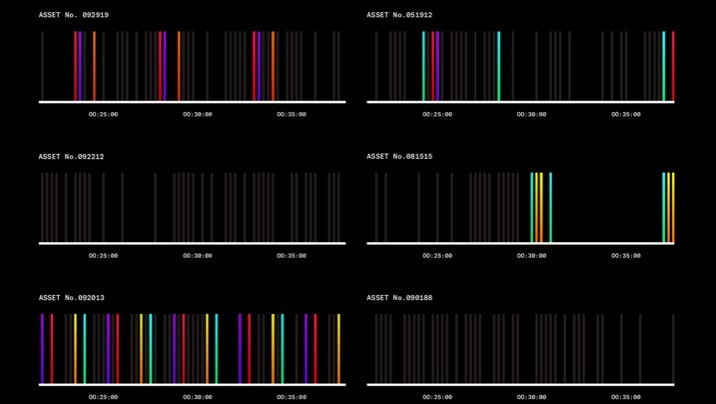

One example of this data overload problem is an abundance of fault code alerts. In Figure 1 (asset sending notifications) and Figure 2 (pattern detected and work order issued), a sample asset is sending a number of alerts and notifications. With access to this data, a subject matter expert can manually review the alerts to find a pattern of alerts that point to an issue. In this example, a potential serpentine belt failure is spotted and a work order for maintenance is scheduled.

This type of predictive capability is valuable. The operator could establish alarm thresholds so that the warning is early enough for the machine to be serviced before it was scheduled to an important job site.

As a result, the operator could prevent significant unplanned downtime on the job site while also providing more robust servicing because they could make sure all the potential failures are addressed before delivering the equipment to a site.

However, this was done for only one machine and this type of manual pattern recognition by a subject matter expert is simply not scalable to an entire fleet of equipment.

Using AI to Scale Machine Monitoring Capacity Across Your Business

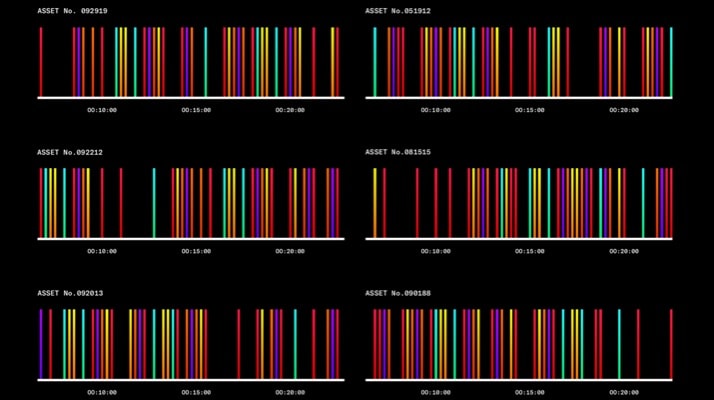

The only way to handle this abundance of data and scale a predictive maintenance solution is through the help of industrial AI. Customers have recognized the value of connectivity for a handful of machines but need an efficient way to scale the knowledge of their subject matter experts to take advantage of all the data available to them from their entire fleet.

Consider a similar array of alarms and fault codes from multiple machines (Figure 3). Additionally, as data is pulled from an entire fleet, the subject matter expert would not only need to recognize a single pattern; but many patterns that could be indicative of future failures. In Figure 4 many different patterns point to the same issue and so are recognized.

Why Industrial AI?

So, how does industrial AI solve this problem? Pattern recognition is a core functionality of industrial AI and can be organized by machine type, subsystem, and failure mode. For example, a library of known failure modes for diesel engines can be referenced and mapped to a signature of identified machine fault codes or alarms. Furthermore, because this pattern recognition is automated, it is consistently replicated across an entire fleet and an ever-expanding library of failure modes.

In fact, the only way to extract value from an abundance of connected machine data is by augmenting subject matter experts with industrial AI capabilities. What’s more, the only way to sustain and grow that value over time is with a robust end-to-end system and business process for implementing industrial AI insights into key-decisions workflows. This is the solution we’ve seen increasingly in demand from construction companies and vital to enabling significant transformation across the industry.

To learn more about how industrial AI solves the data overload problem, click here to download our free white paper.

If you’re interested in learning more about the intersection of technology and construction, CURT’s new Technology and Productivity Committee is focused on exactly this. Technology will also be discussed at CURT’s upcoming National Conference in February 2020 – both on the agenda and in the Exhibit Hall. Register here.

Uptake’s AI-driven software products deliver insights in global industry. Our customers depend on Uptake to increase productivity, reliability, and safety – and we do it by delivering actionable insights to the operational frontline. Recognized for leadership in industrial IoT (IIoT) by the World Economic Forum, CNBC and Forbes, Uptake is headquartered in Chicago, Illinois with a presence in Canada, Europe, and Australia.

Zack Novak is the VP of Construction, Agriculture, and Mining at Uptake. Zack has been with Uptake for four years, joining shortly after the company was founded. Prior to Uptake, Zack was a Business Analyst with McKinsey & Company and played professional basketball in Europe. He graduated with a Bachelor of Business Administration from the University of Michigan, where he was also a three-time captain of the men’s basketball team. Zack presented on this topic on the main stage at CURT’s 2019 National Conference.

CURT’S MISSION IS TO CREATE A COMPETITIVE ADVANTAGE FOR CONSTRUCTION USERS. CURT ACCOMPLISHES THIS MULTIFACETED OBJECTIVE BY PROVIDING AGGRESSIVE LEADERSHIP ON THOSE BUSINESS ISSUES THAT PROMOTE EXCELLENCE IN THE CREATION OF CAPITAL ASSETS.

Very interesting, I am a retired construction manger . I would like to follow your AI future in improving the construction industry. Thanks