By Ken Chapman, Ph.D., and Tony Orlowski, P.E., MBA

This excerpt of “Safety Beyond The Numbers” is printed with permission from the authors and publisher. To purchase your paperback, eBook, or audiobook and learn more about upcoming related seminars, please visit https://www.safepath.solutions.

CURT will be giving away two copies of this book to attendees at their May events. Learn more and register here.

CHAPTER 1

The Night I Cut a Man in Half

I (one of your authors) received the call sometime after midnight (which is never good news). And while I don’t remember the precise time, the conversation remains deeply etched in memory. The voice on the phone said, “Mr. Goode, who runs the separator unit on the production line, got backed into by the roll-off truck. He’s hurt really bad.”

I sat silently on the edge of the bed for a few seconds. Between what the person had just said and being woken up, I truly didn’t understand.

“What are you talking about? That thing moves at only a few feet per second,” I argued. “There’s no way a person could be hit by a backing roll-off.”

“He got pinned,” said the anxious voice on the other end. “I don’t know how.”

I quickly dressed and started driving toward the plant. One part of me wanted to get there instantly while honestly, the other didn’t want to get there at all. It seemed a long drive as my mind raced and familiar landmarks passed slowly. That gave me plenty of time to imagine what I would find when I got there. Scenarios flipped back and forth inside my head from one extreme to another; first visualizing the worst case, then something not so bad, then quickly whipsawing back again. When I finally pulled into the lot, that exercise stopped as I cleared room for the reality that would soon replace my imaginings.

I got out of the car and walked purposefully to the scene of the injury. It was early fall, but more humid than normal. I was sweating. The calmness of the evening in the parking lot contrasted sharply with the bright lights and rushed activity a hundred yards ahead. As I drew closer, I couldn’t shake the feeling I was about to encounter a scene that would stay with me for a long time.

Several people moved about outside. The floodlights cast everything in a harsh monochrome, and a dark pool of blood, black in that light, lay on the ground. Mr. Goode had already been taken to the hospital. I talked with two supervisors who had been first responders.

One, in particular, had acted very quickly to staunch the bleeding. He was ex-military, used to quick judgment in stressful situations, and I believe he saved Mr. Goode’s life. I thanked him for his action, but that was it. He got a two-second thank you. His decision to leave the company a few years later was a loss. He was a good person who deserved more from me, and I regret not telling him how much I appreciated what he did that night.

But it was time to get to work. The first step was to document the incident site. We took pictures of everything. We took video of the truck and the functioning of all safety equipment (lights, backup alarm, etc.), all to show we had followed safety regulations. We were absolutely covering ourselves to control or even preempt our own liability. As callous as that seems now (and was then), it was the right thing to do. We had to protect the company and ourselves. This would be our only opportunity to document the facts, and we knew people might want to argue about them.

By now it was after 2 a.m. and time to visit the hospital. It was as unpleasant as I feared. Meeting the extended family, I told them who I was and that if there was anything I or the company could do for them, we would. We gave them credit for whatever they needed from the cafeteria and provided a place to stay nearby.

Between the crying, I talked mainly with one of Mr. Goode’s daughters because she was fluent in English. She had a toddler who was wandering around oblivious to the sadness in the room. When the little girl tottered over to me, I remember thinking that if she knew who I was, she wouldn’t be looking up at me with that smile. She tripped over my dirty steel-toed boot, and that somehow seemed fitting.

The next day we went to work on the injury site with the goal of making sure nothing like it could ever happen again. This was a long process based on what we pieced together from the incident. Mr. Goode’s job included leaving his normal workstation to hook the truck cable to a large pan when it was full. He would then unhook the truck when the pan was returned empty. The truck had to pull in close for the cable to reach. This night (and perhaps many nights), instead of walking around the truck to return to his workstation, Mr. Goode slid between the rails and the pan. He assumed the driver of the truck knew he was doing this and would wait. The driver did not know.

As Mr. Goode slid behind, the truck started to back up and the narrow rails struck him in the legs just below the torso. He was pinned against the pan and nearly cut in half.

The first thing we did to control this hazard was to remove the help. The driver was now to do this job by himself. We enclosed the pan with railing on three sides so it was difficult to cross in front of the truck. This made the route around the truck the easiest path. We placed a gate in the front so the driver would have to get out of the truck to open it. This ensured there could be no one around when the truck backed up.

About the time we had most of this in place, The Occupational Health and Safety Organization (OSHA) showed up. Our plant as well as other company facilities had been viewed for several years as bad actors. We had had other severe injuries and even a fatality prior to my coming. OSHA now clearly felt they needed to do something, and the Area Director would handle the investigation herself.

After we had walked her through the changes we’d already made, she addressed me with a lot of emotion – a mixture of anger, exasperation, and accusation in her voice. “You had to have known this was a dangerous situation! You put all this up in a matter of days. You had to have known this is what was needed here!”

Until that moment, I hadn’t felt like putting up much of a fight. There was very little criticism I believed would be undeserved. But this struck a chord. “There is no way we ever imagined this would happen!” I said. “We put this up quickly because we have some of the best safety minds in the industry. We’ve put controls in place to eliminate any chance of this happening again, however unlikely.”

She didn’t respond.

Later that evening we reviewed the incident with our attorneys. I spent much of that meeting staring outside into the dark through the glass block office walls. Conversation turned to the area director’s concerns about some of the management team, including me. In fact, as the leader, I was probably a main concern. “Me?” I thought. “But I’m not a bad person! There are plenty of bad people in this world, but I’m not one of them.” That was my first thought. But after dwelling on it a while, I wasn’t so sure.

In this frame of mind, I headed to the hospital again to see how the family was doing. I didn’t want to go. I found them and asked a woman there if I could see the daughter I had spoken with the night before.

“It was ME!” she cried, her tears almost overwhelming her.

I was embarrassed and ashamed that I hadn’t recognized her. Even with everything she was going through — all the anguish and anger — she probably had still wanted to think something good of the company and of me. But I had just confirmed our compassion was all for show. I obviously didn’t see her or her family as individuals, just indistinguishable, interchangeable people among many others. Just as I saw her father, she was sure. I had added insult to injury.

I got home late that night. All the lights were out, and my family was in bed. Leaving the lights off, I sat down at the kitchen table and stared at nothing for a few seconds before bursting out crying. I cried for Mr. Goode. I cried for his family. I cried because I was exhausted and miserable. I was also last on the list of people who deserved to feel sorry for himself. Then I went to bed.

To fast forward, Mr. Goode survived, but fearing infection doctors amputated both of his legs. OSHA found no violations related to the incident, but I became a different person and a different manager than I was before. I questioned all my previous assumptions. And although that left me with several unanswered questions, I became absolutely convinced that at least three things were true:

- It didn’t have to happen. I knew there were thousands of facilities with similar hazards where an injury of this severity had never occurred and likely never would.

- As the facility leader, I was the person with the greatest influence over what did and did not happen at the plant. I was responsible.

- If we did not change significantly in some way, given enough time something similar was going to happen in the future.

I began studying, planning, and championing safety. I doubled down on compliance, going well beyond what was required by regulation to minimize hazards.

I also developed a near-zero tolerance for safety violations. If anyone failed to go along with my newfound commitment to safety, there were severe consequences. If you broke certain safety rules, it was immediate termination without question or exception. Even the smallest infraction could result in formal discipline. I would manage unsafe behavior, if not by reason, by fear of consequence.

And last, I worried. I knew these changes, although extreme, were inadequate for what we needed to accomplish. This couldn’t be it. What it should look like I didn’t know. But one thing I was certain of: there had to be a better way.

Moral Accountability

We opened this chapter with a true story. It is my story. And unfortunately, the most common response to it is sympathy for me. I say unfortunately, because although I was personally impacted, in the end it is not about me. Much more could be written from the perspective of Mr. Goode and his family. But that is a story I do not and cannot fully know. Sympathy for the family is not even the point. It is a point, but it is not the point, because sympathy is not nearly enough.

Most people understand that every injury is a great loss, and a loss that must be accounted for. But few understand the full scope of that accounting. Clearly there are legal and financial components to it. Someone must pay for the medical treatment, lost wages, and other expenses. If there was negligence, a civil case might be brought, or given gross negligence or a willful act, a criminal case might ensue. These are the logical and predictable consequences of any workplace injury. But every conscientious person knows there is another side: a moral component.

People often do not acknowledge this other side of accountability because the two sides are so different. On the legal and financial side, accountability is imposed as a matter of course and precedent. This quality of accountability is fact-based and measurable. Institutions have been created to offer redress to the legal and financial consequences of an injury. Amounts owed are well-established through prior settlements. These aspects of accountability are unavoidable. You can deny the claims leveled against you, and you can defend against them, but you cannot choose to avoid facing them.

The other side of accountability, the moral side, is much different. This side is not as visible or concrete. There are no institutions created to settle these accounts. The accountability is applied naturally, not organizationally. For example, people might not consciously decide to dislike or stop doing business with your company. But that behavior occurs naturally to an organization that is viewed as indifferent to employee injury. Employees likewise may decide to withhold their loyalty or abandon pride of association with such a company, but that is also a natural result.

Because it isn’t structured or immediate, to some this may appear the “soft” side of accountability. Unlike fines and expenses, these accountabilities may appear to be something an organization or individual can walk away from if they choose. But that is an illusion.

Even if an organization does not step up and acknowledge its moral responsibility for an injury, the responsibility does not go away. The debt remains. In a similar way, a leader cannot avoid personal accountability. Without facing up to it and addressing it, they remain diminished in the eyes of everyone they interact with, and probably their own eyes as well.

Why You Are Reading This

You have your own reasons for picking up this book, but we suspect you are reading it for many of the reasons illustrated in this story. Perhaps someone at your facility has suffered a severe injury, and you are committed to ensuring it never happens again. Maybe you have firsthand knowledge of an incident elsewhere and realize it could have just as easily happened to you. Whatever the cause of your concern, you want your people to return home each day safe and uninjured. But you are not confident that will always happen. You are conflicted because although your traditional safety program is supposed to deliver these results (as long as you do your part), you are not confident that ultimately it can.

While many believe an organization’s only responsibility is to make sure OSHA standards are followed, thoughtful leaders know that is not enough. They know it cannot end there. Compliance is a necessary component of safety but is not sufficient by itself. Human behavior plays a major role, and often plays the larger role in safety outcomes. We have understood this for some time.

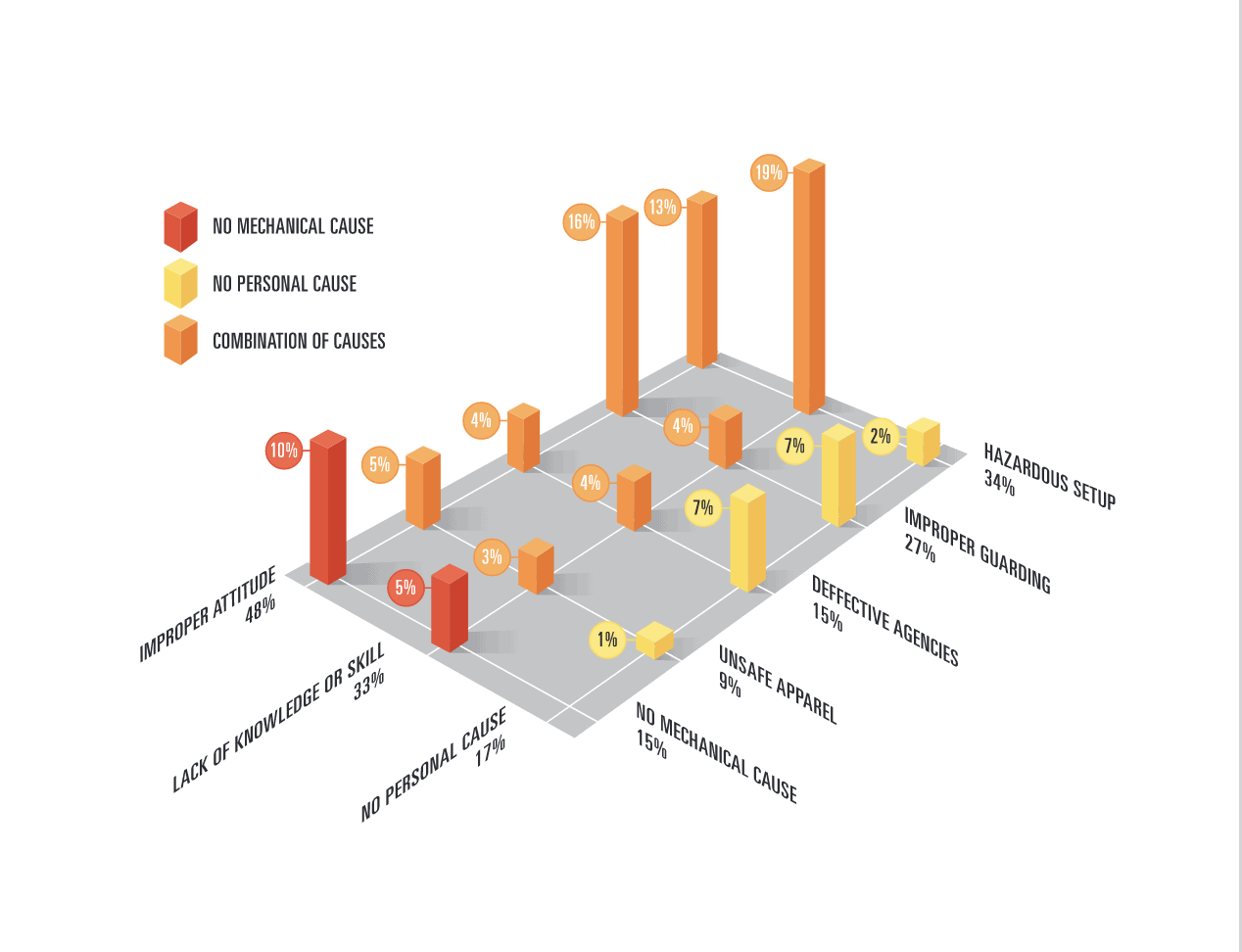

Figure 1.1 is taken from an American Foundrymen Society study of workplace injuries conducted almost 80 years ago. We do not have access to the data used to create this chart, but the results reasonably match our experiences.

The study found that 15 percent of workplace injuries were caused solely by unsafe behavior (personal causes). More than 68 percent were due to a combination of behavior and unsafe conditions. Only 17 percent of injuries in the workplace were caused by unsafe conditions alone — the portion that compliance works on the most!

Most leaders understand this human element, yet are expected to work within a system that essentially ignores it. Being responsible for both a system and for results that the system cannot possibly produce is insanity. The two are incompatible and understandably frustrating for responsible leaders.

A natural result of this frustration is rationalization. If two conflicting premises are presumed true, reality must then be made to fit. These rationalizations often take the form of blaming injuries on fate. The only viable fallback position is that the failure was not preventable. Injury thus becomes an “unfortunate” act of fate.

This is why many organizations label their injuries “accidents.” It supports the idea of lack of control and responsibility. But responsible leaders know those who believe in unfortunate accidents are the ones most likely to have them. They know almost all injuries can be prevented, and that they have a responsibility to ensure consistent safe outcomes. To suggest otherwise is unreasonable.

Finally, realizing safe outcomes is within a leader’s sphere of influence and reasonable people inherently understand the moral responsibility. They are unable to simply move on after dealing with only the financial and legal aspects of an injury. An organization that does not acknowledge and support leaders in meeting this moral responsibility creates even greater frustration.

Good organizations and conscientious leaders know there must be a better way. And the good news is a better way does exist. Most encouraging, not only can it be done, it is being done. Some organizations go years, not just without a significant injury, but without even one that is recordable. These organizations have hazards just as you do. But the hazards are controlled and minimized, and everyone there has a hand in ensuring they remain that way. Their employees also make mistakes just like yours do. But they do not see human behavior as a constraint. They see it as the means, the indispensable component of learning to have safe outcomes.

These organizations do exist. But because their reality differs so much from yours, you might suspect it is not real. They must be “cooking the books,” or not recording all legitimate workplace injuries. In some cases that might be true, but it is certainly not true for all. Some organizations have discovered how to maintain an excellent safety culture where workplace injury is not a common event, but truly an outlier.

It might also be tempting to think these are extraordinary cases created by a talented few. Their leaders possess skills above the level and comprehension of the rest of us. They seemingly “work magic” in ways we will never be able to understand or replicate. But it is not magic. There are fundamental principles which underlie their success that any organization can adopt.

In the following pages, we show there is indeed a better way. We describe principles and practical applications the best organizations have used to consistently achieve superior safety results. Again, no magic is involved. But there is work.

Safety excellence is no easier to achieve than any other type of excellence. It requires hard work and dedication. It is not enough to want safe outcomes. You must be committed to safe outcomes. The two are not the same. Injuries to members of your team must not be just undesirable to you, they must be unacceptable to you. In the words of Vince Lombardi:

“Most people fail not because of a lack of desire, but because of a lack of commitment.”

Cutting a man in half can do wonders for your commitment. The tough decisions and hard work required for safety excellence are difficult for some leaders to accept, but they are easy for a person who has cut a man in half. Of course that is not the path anyone should wish for as a starting point to this journey. And it is by no means necessary. Our history tells us that much.

KEY IDEAS

- Excellent compliance does not equal excellent safety outcomes.

- Sympathy is not enough. As a leader, you are accountable for taking action to mitigate the loss of life, health, and human potential.

- Following laws and regulations is only part of that accountability. Safety is a moral obligation.

- Improving safety outcomes is not magic, but it is work. You must commit to it as you would any other important organizational goal.

Ken Chapman, Ph.D., is the Founder and Senior Partner of Ken Chapman & Associates, Inc. Along with more than forty years of consulting, Dr. Chapman brings the following experiences to client service: supermarket bag-boy, frontline supervisor, corporate vice president, and university professor. As a consultant, Dr. Chapman focuses on heavy industry, having provided leadership and team development in more than 400 electric generating stations, foundries, paper mills, refineries, and manufacturing facilities.

Tony Orlowski is the Executive Vice President, Plumbing Group of McWane, Inc. In this role he has overall responsibility of the AB&I Foundry and Anaco-Husky facilities in California, Texas-based Tyler Pipe & Coupling plants, and the Sri City, India, Coupling plant, which combined account for more than 1,400 team members manufacturing drainage, waste and venting products for the commercial plumbing industry.